Category Archives: Forklifts

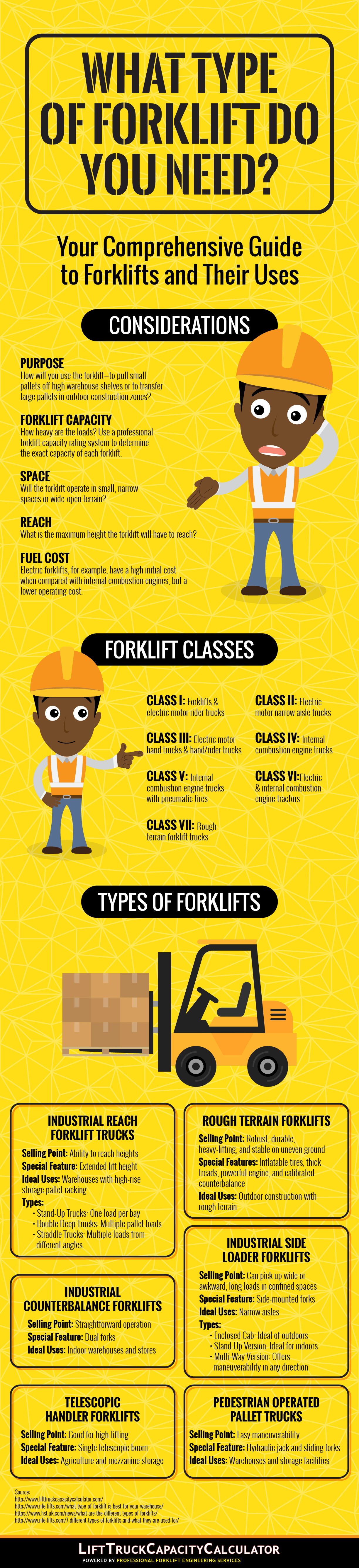

When you are in need of machinery to move products and other materials around your business or job site, using a forklift is one of the easiest and most efficient options. However, with the variety of forklifts available for the job, it can be difficult to decide which will be best for your situation. In order to solve this problem, it is important to consider a few factors.

Start by assessing the purpose of the forklift. Do you need it to pull pallets from a shelf or move large pallets around a construction site? What load capacity is needed to get the job done correctly and safely? Don’t forget to note the size of the space in which the forklift will operate. Choosing one too large will negate any benefits you hope to receive.

You also want to ensure that you have certified forklift operators who can easily operate the lift to help you cut down on time and expenses along the way. Research the type of forklifts available and assess your individual needs before buying or leasing for your company.

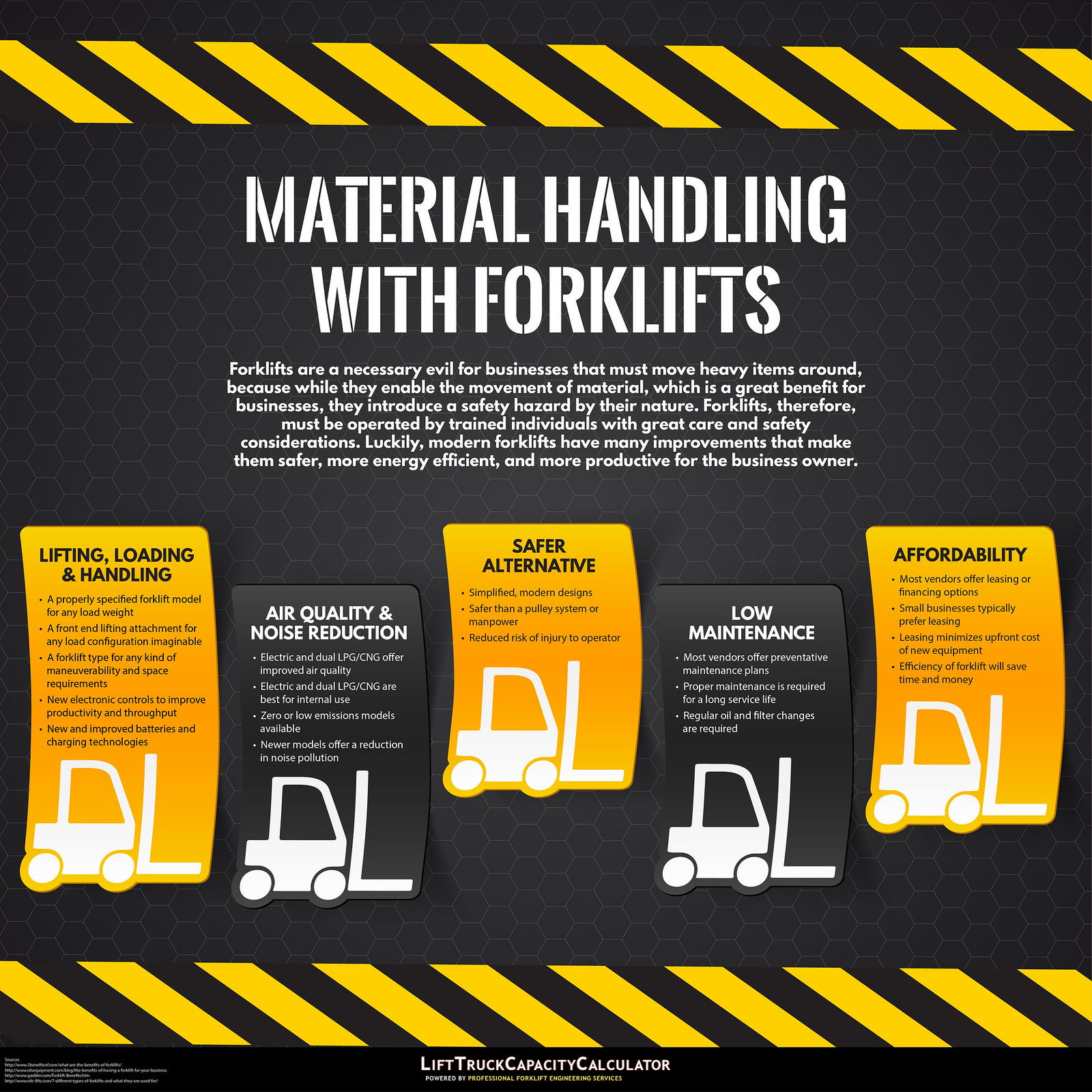

Moving materials and items around a business, warehouse, or job site is necessary for work to be done in many businesses. This means that companies rely on forklifts to move materials, but since safety is always concern and a priority for businesses, they must practice safety to minimize risk to employees and materials. Over time forklifts have become progressively more advanced and safer for operators, but lifting, lowering and moving heavy material with forklifts is precarious by nature, and thus requires skill, care, training and knowledge to be executed safely and efficiently.

First and foremost, the operator should always be aware of the load weight limits specified on the forklift data plate or data label for the particular forklift. Different types of lift trucks have different parameters for maneuverability, operation and safety, and the operator should aware, trained and comfortable with the operation the particular forklift machine. New forklift designs simplify the learning process for operators and deliver greater benefits for companies. For growing businesses, many different machine acquisition options are available to fit the business owners needs. Forklift acquisition should always be done through local dealers and sellers who can review the onsite requirements of the business owner, and provide the necessary local service and support required to keep the forklifts in good operating condition.

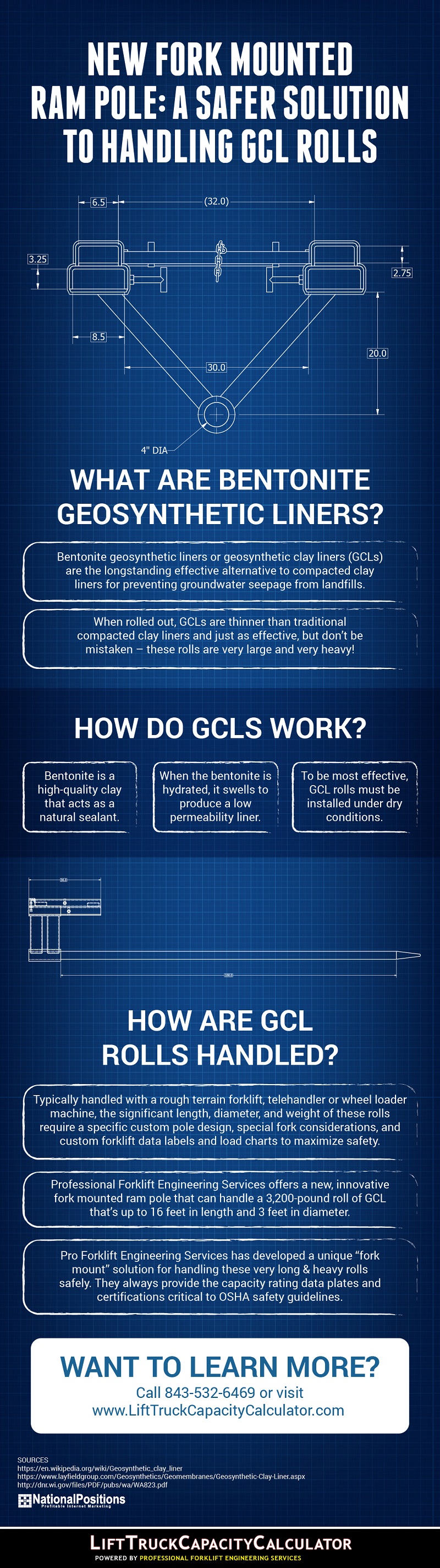

Lift Truck Capacity Calculator’s new fork mounted ram polls address the problem presented by heavy rolls of Bentonite geosynthetic liners or geosynthetic clay liners, commonly referred to as GCLs. GCLs are essential components of modern landfills, helping to contain their contents and prevent groundwater seepage.

GCL rolls are less heavy than traditional clay liners but are still very heavy. Safely handling these rolls poses a challenge for contractors working in the rough terrain typically associated with landfills. Lift Truck Capacity Calculator’s new fork mounted ram roll is specially designed to handle GCLs. The new product can safely lift GCLs up to 3,200 lbs., 16 feet wide, and three feet in diameter. Careful consideration must be exercised in designing an attachment for this application and Pro Forklift Eng Svcs has a certifiable solution available. To learn more about

Lift Truck Capacity Calculator’s innovative new fork mounted ram roll; take a look at this easy-to-understand infographic.

Stability when driving a forklift is essential so that your operators do not tip when moving a load from one place to another. There are certain design stability requirements set by the industry and manufacturers that are in place for each specific type of powered industrial truck. The term ‘design stability’ refers to the measurement of a truck’s resistance to overturning under controlled circumstances. Here are a few factors that can influence stability:

- Weight Distribution

- Truck Speed

- Wheelbase

- Suspension Method

- Wheel Tread

Taking these factors and more into account, forklifts and other industrial trucks are tested and inspected to determine stability. A tilting platform test verifies stability and can also be used to enhance forklift design to better meet the needs of operators and warehouses. Various test values are also calculated to forecast prevision and stability, followed by tests to confirm that weight distribution and other factors are adequately maintained.