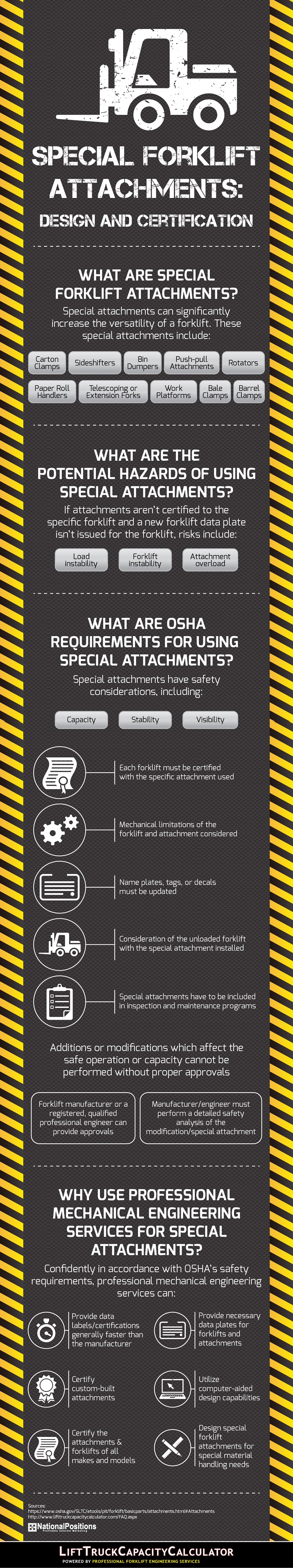

If your company uses a forklift, you know how important this piece of equipment is to your business and how versatile it can be with the use of special forklift attachments. These special attachments are used to transform from simple lifting forks, into a multi-purpose machine designated for a very particular task.

The different types of special forklift attachments are virtually unlimited but typical attachments include side shifters, fork positioners, rotators, paper roll clamps, box clamps, bale clamps, appliance clamps, concrete block clamps, push-pulls (also called slip-sheet attachments), load extenders and stabilizers, hay clamps, bale spears, carriages, skips or waste bins, scoops, buckets, booms, crane jibs, fork mounted hooks, forks, fork extensions, bulk bag handlers, snow ploughs, yard scrapers, fork mounted drum handlers and drum rotators, work platforms and cages just to name a few. Special custom made and in-house fabricated attachments are also often used.

If you need to use special forklift attachments, you will also need to certify and label the forklift with an updated data plate to reflect the new forklift configuration and the new lifting capacity. Updating the data plate when you change front end attachments is an OSHA regulation that falls under OSHA regulation CFR 29 1910.178 referencing “powered industrial truck addition/modification approval and marking requirements”. Professional Forklift Engineering Services has qualified professional engineers that can help you get your forklifts OSHA compliant in this regard.

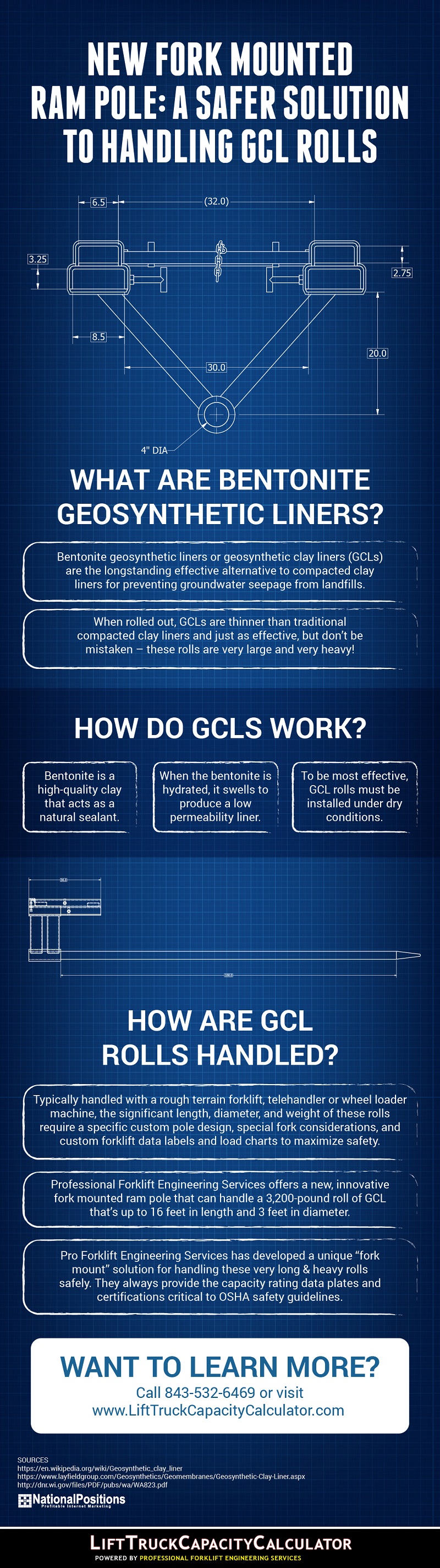

Lift Truck Capacity Calculator’s new fork mounted ram polls address the problem presented by heavy rolls of Bentonite geosynthetic liners or geosynthetic clay liners, commonly referred to as GCLs. GCLs are essential components of modern landfills, helping to contain their contents and prevent groundwater seepage.

GCL rolls are less heavy than traditional clay liners but are still very heavy. Safely handling these rolls poses a challenge for contractors working in the rough terrain typically associated with landfills. Lift Truck Capacity Calculator’s new fork mounted ram roll is specially designed to handle GCLs. The new product can safely lift GCLs up to 3,200 lbs., 16 feet wide, and three feet in diameter. Careful consideration must be exercised in designing an attachment for this application and Pro Forklift Eng Svcs has a certifiable solution available. To learn more about

Lift Truck Capacity Calculator’s innovative new fork mounted ram roll; take a look at this easy-to-understand infographic.

Stability when driving a forklift is essential so that your operators do not tip when moving a load from one place to another. There are certain design stability requirements set by the industry and manufacturers that are in place for each specific type of powered industrial truck. The term ‘design stability’ refers to the measurement of a truck’s resistance to overturning under controlled circumstances. Here are a few factors that can influence stability:

- Weight Distribution

- Truck Speed

- Wheelbase

- Suspension Method

- Wheel Tread

Taking these factors and more into account, forklifts and other industrial trucks are tested and inspected to determine stability. A tilting platform test verifies stability and can also be used to enhance forklift design to better meet the needs of operators and warehouses. Various test values are also calculated to forecast prevision and stability, followed by tests to confirm that weight distribution and other factors are adequately maintained.

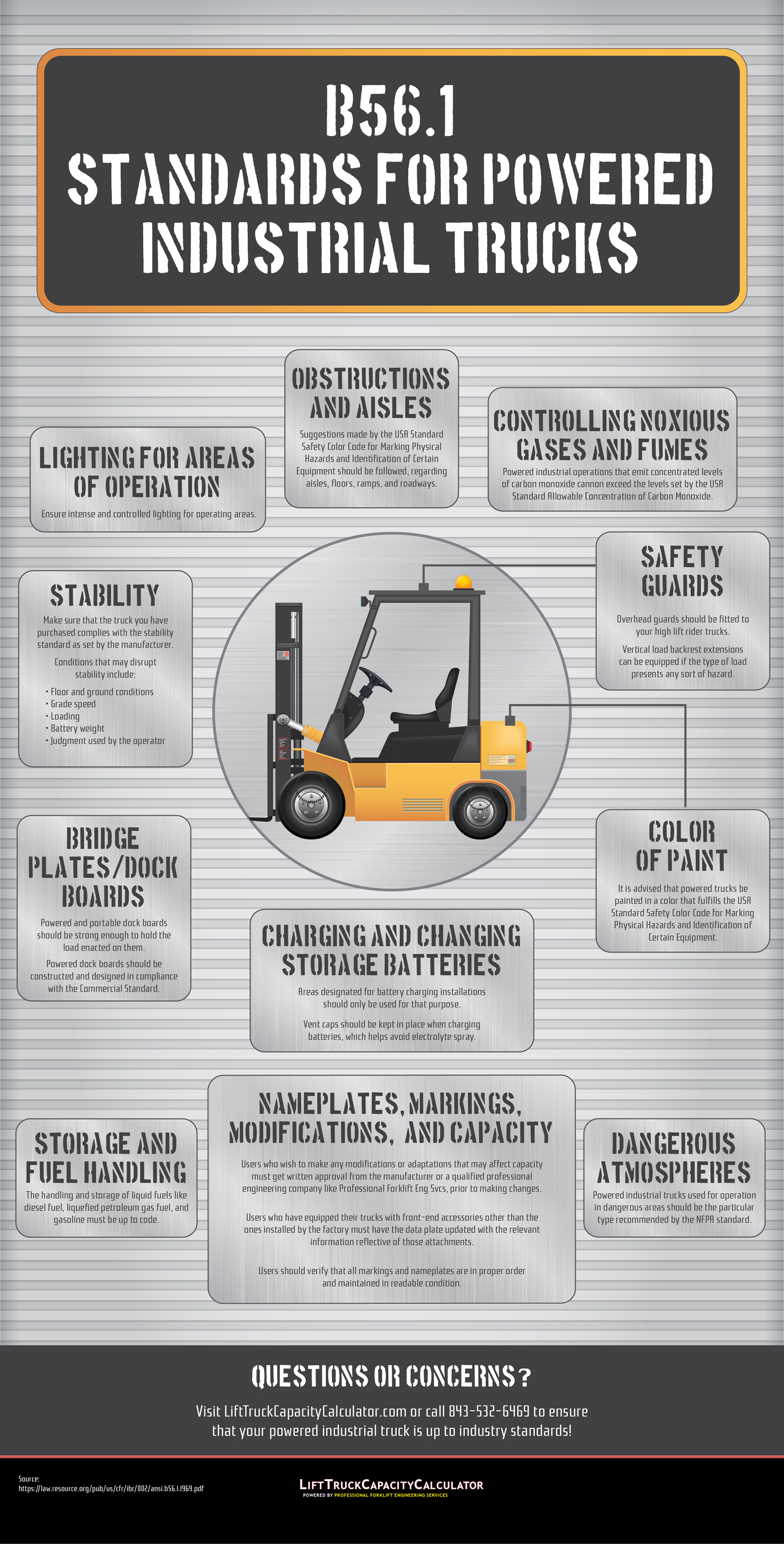

Ensuring that you follow all safety standards and regulations in your warehouse is essential in order to maintain compliance and reduce the risk of injury to your employees. In addition to organizing storage spaces and improving workplace efficiency, understanding the standards set for powered trucks and forklifts will promote safety and increase accountability for your business. These govern everything from workplace lighting, to the storage, to the color of paint on the vehicle. Here are just a few to become familiar with:

- The USA Standard Safety Color Code for Marking Physical Hazards and Identification of Certain Equipment should be followed in relation to obstructions and aisles.

- Areas designated for battery charging and installations should only be used for that purpose.

- Ensure that the storage and handling of fuel, such as diesel and gasoline, are up to code.

Be sure that your management team and employees are aware of the various safety standards in place for the storage and operation of powered industrial trucks in order to avoid potential injury and loss for your organization.

Understanding the lateral stability of a forklift is essential in order to ensure that operators complete jobs safely when using the equipment. The best way to think about lateral stability for a forklift is to compare it to your car. When you make this comparison, you can see that a forklift is narrower, higher up, and without suspension to handle bumps. Therefore, it is crucially important for an operator to practice safe driving techniques so the lift does not overturn.

Driving and turning at a reasonable speed, as well as exercising caution on slopes, will help maintain the center of balance for the forklift. That way, each job can be safely completed while eliminating the risk of dropping the load or crashing. Be sure to read all safety information when using a rotational attachment, and perform a thorough equipment check before operating the forklift, so that any potential risks can be assessed by management if needed.

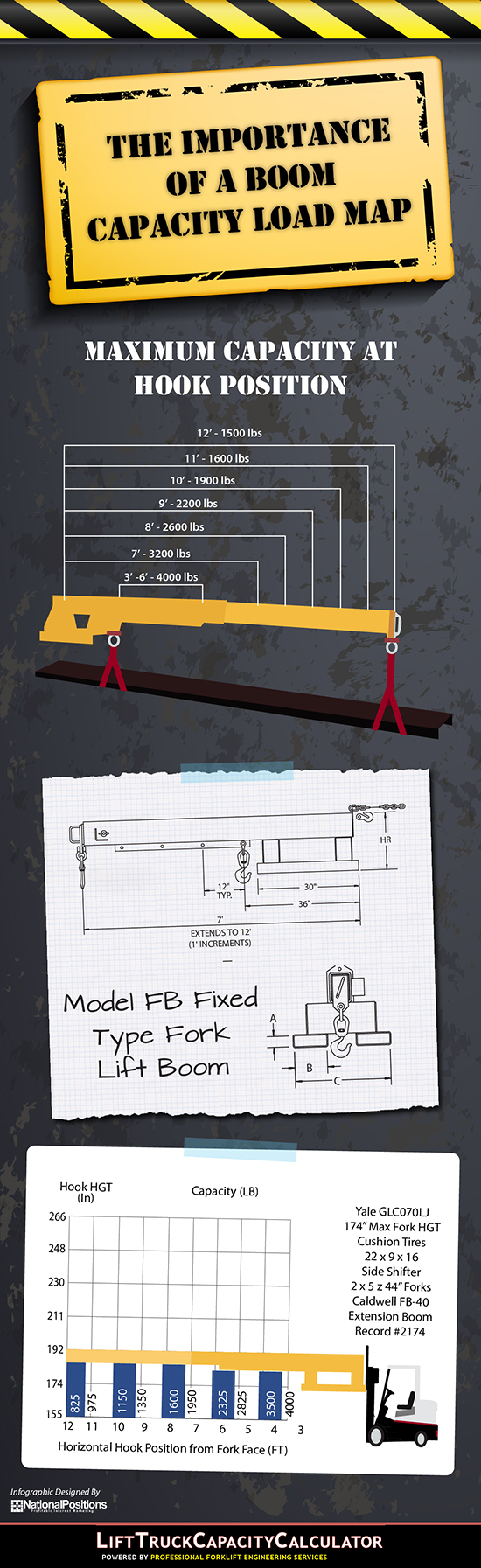

Understanding the capabilities and limitations of your machinery before use allows your employees to safely complete tasks. In addition, your business will see a decreased risk of injury, leading to greater productivity and efficiency. A boom capacity load map helps you achieve these goals, by giving your employees the information they need so they can safely lift materials in the warehouse or out on a job site.

Affixed to the forklift, the boom capacity load map shows the safe amount of weight that can be lifted at certain hook position intervals. The size of the load will affect the hook position, and you want to be sure to never lift over the capacity so that the highest levels of safety can be maintained at all times. Continually educating and retraining employees on the various equipment they use will ensure proper usage, and save time and money lost from injuries and broken machines.

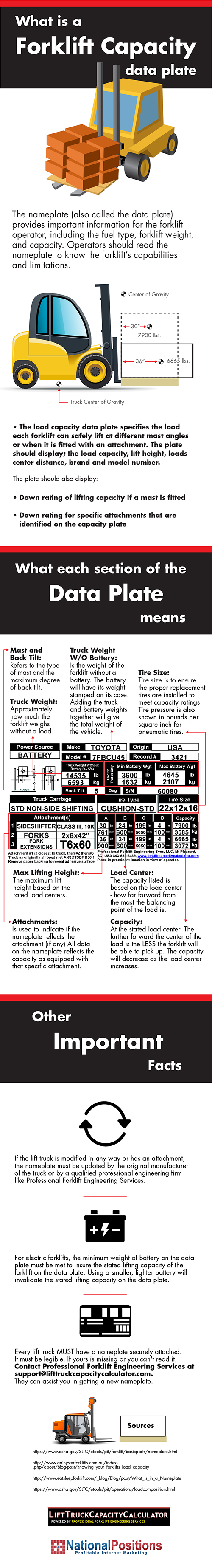

The data plate on a forklift is broken down into different sections, which each stand for a different characteristic and measurement. Some of these include:

Mast and Back Tilt Refers to the type of mast and the maximum degree of back tilt allowable.

Tire Size Ensures proper replacement tires are used to maintain levels of safety.

Load Center Gives a capacity based on how far forward from the mast the balancing point of the load is.

If any modifications are made to a forklift, or if it has an attachment, the forklift capacity plate must be updated to reflect the new capacity. Similarly, if a data plate goes missing or is illegible, you are required to replace it. To do so, contact Professional Forklift Engineering Services at support@lifttruckcapacitycalculator.com.