When working in a warehouse, or for any business that owns and operates forklifts, taking proper safety precautions is of the utmost importance. Owners of forklifts need to ensure that operators are fully trained and authorized to work with the equipment in order to meet compliance standards. Additionally, work areas should be cleared of debris and clutter, to allow forklifts to move and operate freely. This helps reduce the number of injuries and keeps employers and employees aware of best practices for operation at all times.

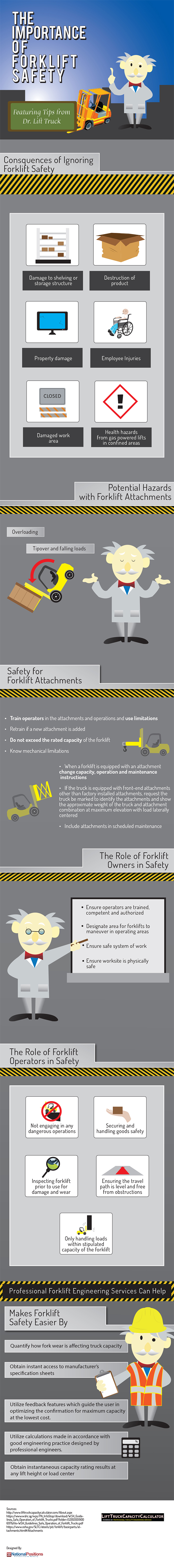

If forklift safety plans are ignored, there are a number of potential consequences, including:

Damage to warehouse shelving or storage structure

Destruction of product

Property damage

Employee injuries

Damaged work area as a result of spills or broken shelving

Health hazards

In addition, overloading a forklift could cause it to tip over. Damaged products and equipment will end up costing your business more in repair and replacement costs, which can be avoided by taking the time to do the job the right way.

Forklift attachments should be inspected regularly so that repairs to broken forks and other equipment can be made immediately. Train all operators on your attachments and, when you add a new attachment, be sure to retrain all personnel. Know the mechanical limitations of each forklift, and change the capacity, operation, and maintenance instructions when a forklift is equipped with an attachment.

Forklift operators should remain safe when driving a forklift, and they should secure all products before transporting. Inspect the forklift before each use, and always ensure the travel path is free of obstructions before beginning a job.